Technologies

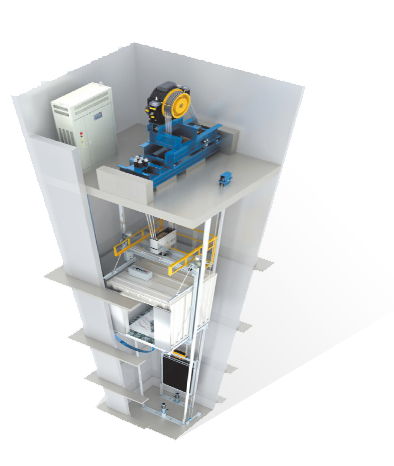

Machine Roomless Elevators – MRL

Machine Room-Less Elevator Systems, or MRL, are designed to address several common challenges with elevator installation, such as limited space in small or old buildings, and to facilitate installation and maintenance. Because there's no need for a separate machine room, this can also provide some architectural benefits, providing more usable space in the building where the elevator is installed. In this system, the Gearless motor is usually placed in the same technical shaft where the elevator also moves.

Machine Room Elevators – MR

The Machine-Room Elevator system, or MR, is a type of elevator system where the elevator machinery equipment is placed within a separate room. This dedicated room is used to house the motor and electrical equipment, and other necessary control devices for the operation of the elevator. The use of a technical room serves the purpose of performing periodic services and maintenance of the elevator since technicians can have direct access to the machinery equipment.

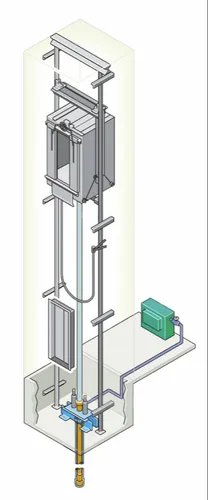

Hydraulic Driven Elevators

The Hydraulic Elevator System is recommended for cases where buildings have 2-3 stops and tonnage capacities such as for goods or vehicles. The advantages of this system include its speed compared to electric systems and maintenance cost.

Elevator Control Systems

Elevator Control Systems are sophisticated systems that control the movement and operation of elevators. These systems are used to ensure that elevators operate safely, efficiently, and respond to users' needs. Some important elements of elevator control systems include:

1-Level Controls: The control system monitors and manages the elevator's movement between different levels of the building. This includes identifying and stopping the elevator at desired floors, as well as coordinating the opening and closing of elevator doors.

2-Call-Button System: Call buttons are part of the access control system for users. The control system must interpret requests and direct the elevator to fulfill the call.

3-Safety System: The control system also includes safety features that ensure the elevator operates safely for users.

4-Monitoring System: Some elevator control systems are linked to monitoring systems that monitor the elevator's performance and identify potential maintenance issues or technical defects.

5-Advanced Technologies: Elevator control systems also include advanced technologies such as artificial intelligence and energy usage methods to improve efficiency and provide a better experience for users.

These elements constitute an integrated system that controls all aspects of elevator movement and operation to ensure a safe and fast journey for passengers.

Gearless Engine Technology

Gearless System technology is a significant innovation that has deeply influenced the performance and design of elevators. The characteristics of this technology include:

1-Energy Efficiency: The control system monitors and manages the elevator's movement between different levels of the building. This includes identifying and stopping the elevator at desired floors, as well as coordinating the opening and closing of elevator doors.

2-Speed and High Performance: Gearless motors offer higher speed and improved performance compared to traditional motors. This allows elevators to achieve higher speeds and provide a higher and faster journey for passengers.

3-Stability: This system technology tends to be less prone to technical issues and requires less maintenance. Furthermore, this technology provides a smoother and more stable ride for passengers.

4-Design Advantages: Due to the use of a more compact and lighter motor, elevators with Gearless technology offer greater opportunities for aesthetic design and more efficient use of spaces in buildings.

This technology has transformed the elevator industry by providing high fulfillment of the needs for speed, safety, and energy